How Slabs of Quartz Stone Are Manufactured and Engineered

- From Raw Materials to Finished Surfaces

- Overview: What is a slab of quartz stone and why it matters

- Manufacturing steps for a slab of quartz stone

- 1. Raw material selection and preparation (: slab of quartz stone purchases)

- 2. Batching and blending: consistency is engineered

- 3. Vibrating and compacting into molds: the heart of slab formation

- 4. Curing and demolding: chemical and thermal control

- 5. Surface finishing: calibrating thickness and texture

- 6. Quality control and testing (embed : slab of quartz stone quality)

- Engineering properties that make a slab of quartz stone perform

- Composition and typical material proportions

- Mechanical and surface performance

- Health, safety and environmental aspects during manufacture

- Regulatory and safety references

- Comparing a slab of quartz stone with alternatives (data-driven purchasing)

- Fabrication best practices for installers working with a slab of quartz stone

- Warranty and product documentation (: slab of quartz stone supplier)

- Bellastone: a profile of a professional slab of quartz stone manufacturer and supplier

- Why choose Bellastone (competitive advantages)

- How to specify and buy a slab of quartz stone for your project

- FAQs

- 1. What exactly is a slab of quartz stone made of?

- 2. How does the manufacturing process affect the durability of a slab of quartz stone?

- 3. Is engineered quartz heat resistant?

- 4. Can slabs of quartz stone be repaired if damaged?

- 5. How do I verify quality when buying a slab of quartz stone?

- 6. Are there sustainable or recycled quartz slab options?

- Contact and product inquiry (CTA)

- References

From Raw Materials to Finished Surfaces

Overview: What is a slab of quartz stone and why it matters

A slab of quartz stone refers to an engineered surface panel made primarily from natural quartz aggregates bound with polymer resins and performance additives. Unlike natural quarried stone, engineered quartz slabs are man-made and controlled to achieve consistent color, pattern, and enhanced performance such as improved stain resistance, non-porosity, and mechanical strength. For architects, fabricators, suppliers, and end users, understanding how a slab of quartz stone is manufactured and engineered helps assess quality, durability, cost drivers, and sustainability trade-offs.Once you know how slabs of quartz stone are manufactured and engineered, you can explore the latest quartz slab design trends: colors, patterns and finishes. These design trends will help you select the perfect quartz slab to complement your kitchen’s aesthetic.

Manufacturing steps for a slab of quartz stone

The production of a slab of quartz stone follows several deliberate stages. Each stage impacts final properties such as strength, porosity, and appearance. Below are the core steps with practical details that matter to buyers and specifiers.

1. Raw material selection and preparation (: slab of quartz stone purchases)

Primary inputs are crystalline quartz aggregates, polymer resin (commonly polyester or epoxy-based), pigments, and performance additives (UV stabilizers, catalysts, inhibitors). Typical engineered quartz content ranges from about 85 to 95% natural quartz by weight; resins and additives make up the remainder. High-quality slabs start with well-graded quartz granules and strict contamination control. Impurities, moisture, or inconsistent grain-size distribution can produce defects or weak spots.

2. Batching and blending: consistency is engineered

Batches are weighed precisely using automated feeders: quartz aggregates, pigments, resins, and additives are mixed to a target formula. For production-scale lines, continuous mixing with controlled residence time ensures color uniformity. Manufacturers often maintain master formulations to reproduce colors and engineered properties across production runs.

3. Vibrating and compacting into molds: the heart of slab formation

After blending, the mix is placed into slab molds. Most modern lines use vibro-compression under vacuum to remove entrapped air and achieve high density. Vacuum vibro-compression compresses the mix while vibrating it, producing slabs with low porosity and high flexural strength. Process variables include vacuum level, vibration frequency, and compaction pressure. These parameters are tuned to the specific resin system and quartz grain size.

4. Curing and demolding: chemical and thermal control

Once compacted, slabs are cured to polymerize the resin binder. Curing can be performed at ambient temperatures for long cycles or accelerated in curing ovens. Proper curing is crucial for bonding strength and stability; undercured slabs may delaminate or have poor chemical resistance, while overcuring can cause brittleness. After curing, slabs are demolded and undergo initial inspection.

5. Surface finishing: calibrating thickness and texture

Finished slabs are calibrated to target thicknesses using gang saws or CNC trimming. Surface finishes include polished, honed, leathered, or textured. Polishing removes surface micro-roughness and enhances visual depth; honing yields a matte look. Surface finish selection affects aesthetics and functional properties like slip resistance and cleanability.

6. Quality control and testing (embed : slab of quartz stone quality)

Quality control covers visual inspection, dimensional checks, mechanical testing (flexural strength, modulus), and surface performance tests (stain resistance, scratch resistance). Many manufacturers follow ISO or ASTM guidelines for engineered stone testing. Data sheets should provide values for water absorption, flexural strength, and specific gravity so specifiers can compare products objectively.

Engineering properties that make a slab of quartz stone perform

Understanding engineered properties is essential when specifying quartz for kitchens, bathrooms, or commercial interiors. The engineered nature of quartz slabs enables tailoring of mechanical and aesthetic properties that are difficult to achieve in natural stone.

Composition and typical material proportions

Typical composition by weight for commercial engineered quartz slabs:

| Component | Typical range (%) |

|---|---|

| Crystalline quartz | 85-95 |

| Polymer resin (polyester/epoxy) | 5-10 |

| Pigments, additives, binders | <5 |

Sources: industry publications and engineered stone references; composition varies with brand and product line. Exact formulations are often proprietary but the high quartz content is the defining characteristic.

Mechanical and surface performance

Key engineered properties buyers reference include:

- Flexural strength: engineered slabs typically exhibit higher and more consistent flexural strength than many natural stones due to uniformity and resin binding.

- Water absorption: low water absorption (near zero) makes quartz slabs highly stain-resistant compared with porous natural stones.

- Hardness and scratch resistance: high quartz content provides strong resistance to abrasion; however fine scratches may still occur, depending on resin content and finish.

- Chemical resistance: cured resins determine resistance to household acids, cleaners, and solvents; quality resins and proper curing improve resistance.

Health, safety and environmental aspects during manufacture

Manufacturing a slab of quartz stone raises occupational safety issues, especially respirable crystalline silica exposure during cutting, grinding, and polishing. Regulatory agencies such as OSHA and health authorities provide exposure limits and control recommendations. Best practices include wet cutting, local exhaust ventilation, and respiratory protection for workers. Waste management, resin VOC controls, and energy use are environmental considerations; some manufacturers pursue recycled content and energy-optimized curing to reduce footprint.

Regulatory and safety references

Follow applicable silica exposure rules and documentation for fabrication shops. Fabricators should consult and comply with local OSHA or equivalent regulations, and implement engineering controls and training.

Comparing a slab of quartz stone with alternatives (data-driven purchasing)

When choosing surfaces, comparing engineered quartz to granite and marble helps clarify tradeoffs. The table below summarizes typical characteristics relevant to specifiers and purchasers.

| Property | Engineered quartz (slab of quartz stone) | Granite | Marble |

|---|---|---|---|

| Porosity | Very low (non-porous) | Variable, often higher | High |

| Stain resistance | High | Moderate (requires sealing) | Low (acid susceptible) |

| Color consistency | Very consistent (engineered) | Natural variation | Natural variation |

| Heat resistance | Good, but sensitive to thermal shock | Excellent | Good |

| Maintenance | Low | Medium (sealing) | High |

| Typical use | Kitchens, bathrooms, commercial counters | Kitchens, exteriors, monuments | Bathrooms, decorative surfaces |

Data sources summarized in References. Choosing the right material depends on project priorities such as appearance, maintenance, and budget.

Fabrication best practices for installers working with a slab of quartz stone

Good fabrication practices reduce waste, ensure fit, and preserve warranty coverage. Key recommendations:

- Plan templates digitally to minimize seams and optimize yield.

- Use diamond tooling and proper feed rates to reduce chipping.

- Employ wet cutting or effective dust collection to control silica dust.

- Follow manufacturer guidance for seam adhesives, backing supports, and allowable overhangs.

Warranty and product documentation (: slab of quartz stone supplier)

Reputable manufacturers supply technical datasheets and warranty terms that define permitted fabrication methods, maintenance requirements, and limitations (e.g., heat exposure). Always request and retain manufacturer technical documents and installation guides to ensure compliance and preserve warranty coverage.

Bellastone: a profile of a professional slab of quartz stone manufacturer and supplier

Guangdong Bellastone Green Building Material Co., Ltd. is a professional quartz slab manufacturer and supplier, specializing in the research & development, production, processing, and marketing of High Quality quartz surfaces for 10 years. Strategically located in the First Area of Enping Zone, Jiangmen Transfer Industrial Park, Jiangmen, Guangdong Province, our company spans approximately 30,000 square meters and is equipped with three internationally advanced quartz production lines.

Our products feature innovative and unique designs, combining aesthetic appeal with uncompromising quality. As a result, Bellastone quartz surfaces are widely favored by both domestic and international customers. We also maintain a showroom in CCIH, Foshan, Guangdong, to showcase our latest collections and facilitate customer engagement.

Bellastone offers a diverse range of high-quality quartz surfaces tailored to meet a variety of aesthetic and functional requirements. From bold contemporary styles to timeless classics, our product lines include: Carrara-inspired marble looks, industrial concrete textures, vibrant printed designs, subtle and sophisticated tones.

Each slab is engineered for durability, stain resistance, and long-term performance, making our quartz ideal for use in kitchens, bathrooms, commercial spaces, and more.

Why choose Bellastone (competitive advantages)

Bellastone combines manufacturing scale, process control, and design innovation. Key differentiators:

- Production capability: three advanced production lines enabling consistent quality and timely lead times.

- Design and R&D: in-house design development that produces market-relevant visuals from Carrara-style veining to bold contemporary patterns.

- Quality control: standardized testing and finish calibration to meet international expectations for engineered stone.

- Showroom and customer engagement: accessible Foshan showroom for product review and specification support.

Main product categories: artificial quartz stone, engineered stone, and quartz stone slabs. Advantages include low porosity, high durability, consistent color, and a wide palette of available designs suited for residential and commercial projects.

How to specify and buy a slab of quartz stone for your project

Steps to ensure you obtain the right slab for performance and aesthetics:

- Define project priorities: appearance, maintenance, budget, heat exposure, and expected traffic.

- Request technical datasheets: water absorption, flexural strength, surface hardness, warranty terms.

- Ask for full slabs or digital color profiles: inspect actual slabs when possible; photos can be misleading for veined designs.

- Confirm fabrication support: compatible adhesives, recommended tooling, and allowable overhangs.

- Check lead times and logistics: slab dimensions, shipping constraints, and safe handling requirements.

FAQs

1. What exactly is a slab of quartz stone made of?

Most slabs are about 85-95% natural crystalline quartz combined with 5-15% polymer resins and small amounts of pigments and additives. Exact formulations vary by manufacturer and product line.

2. How does the manufacturing process affect the durability of a slab of quartz stone?

Key process steps—grain selection, vacuum vibration compaction, and proper curing—directly determine density, porosity, and bonding quality. Precise process control yields more durable, less porous slabs with consistent mechanical properties.

3. Is engineered quartz heat resistant?

Quartz slabs resist everyday heat but are not immune to thermal shock from very hot pots placed directly on the surface. Use trivets or hot pads to prevent thermal damage and possible resin discoloration or cracking.

4. Can slabs of quartz stone be repaired if damaged?

Minor chips and scratches can often be repaired by trained fabricators using color-matched resins and polishing. Deep cracks or extensive damage may require slab replacement.

5. How do I verify quality when buying a slab of quartz stone?

Ask for datasheets, test reports (water absorption, flexural strength), and warranty terms. Inspect full-size slabs where possible and verify that the supplier complies with health and safety practices during fabrication.

6. Are there sustainable or recycled quartz slab options?

Some manufacturers incorporate recycled content (glass or reclaimed quartz) and pursue energy-efficient production. Sustainability varies by brand, so request environmental product declarations if sustainability is a priority.

Contact and product inquiry (CTA)

For project quotes, technical datasheets, or to view Bellastone collections in our Foshan showroom, contact Bellastone sales and technical team. Visit our showroom at CCIH, Foshan, or request product samples and fabrication guidance for your next project. Email or phone details are available from our corporate contact page.

References

- Caesarstone, How It's Made: overview of engineered quartz production processes. Accessed 2025-11-24. https://www.caesarstone.com/about/how-its-made/

- Engineered stone, Wikipedia: composition and industry overview. Accessed 2025-11-24. https://en.wikipedia.org/wiki/Engineered_stone

- Occupational Safety and Health Administration (OSHA), Crystalline Silica Standard and guidance. Accessed 2025-11-24. https://www.osha.gov/silica-crystalline

- Grand View Research, Quartz Surfaces Market Analysis: market trends and outlook. Accessed 2025-11-24. https://www.grandviewresearch.com/industry-analysis/quartz-surfaces-market

- Industry technical notes and fabrication best practices from leading engineered stone manufacturers, various product technical datasheets. Accessed 2025-11-24.

Best quartz slabs manufacturers and supplier brands

Top 10 quartz stone slab for kitchen Manufacturers and Supplier Brands

Aesthetic Consistency: Managing Carrara Veining in Bulk Orders

Repair and Restoration Options for Damaged Calacatta Quartz

Care & Maintenace

Is Bellastone quartz heat-resistant?

Quartz is heat-resistant, but not heat-proof. Always use trivets or hot pads to protect the surface from direct heat or hot cookware.

Printed Artificial Quartz Stone

How does printed quartz compare to natural marble?

Printed quartz offers better consistency, lower maintenance, and higher resistance to stains and scratches, while delivering a similar visual effect.

Is it suitable for commercial projects?

Absolutely. Its uniform appearance, durability, and scalability make it ideal for hotels, offices, retail, and large construction projects.

What is printed quartz stone?

Printed quartz stone is an engineered quartz slab with high-definition printed surface patterns that simulate natural stone aesthetics while maintaining quartz performance.

FAQ

How to clean and maintain quartz stone?

Routine maintenance is quite straightforward:

Regular cleaning: Wipe with a soft cloth and neutral detergent, no special maintenance agent required

Stubborn stains: Use special cleaning paste for stone materials, avoid using strong acid or alkali products

Repair suggestion: If superficial scratches are accidentally caused, contact a professional for surface polishing repair

Precautions: Avoid leaving high-temperature cookware on the stove for extended periods (it is recommended to use a trivet). Do not

BELLASTONE Artificial Quartz Stone Printed Quartz Collection

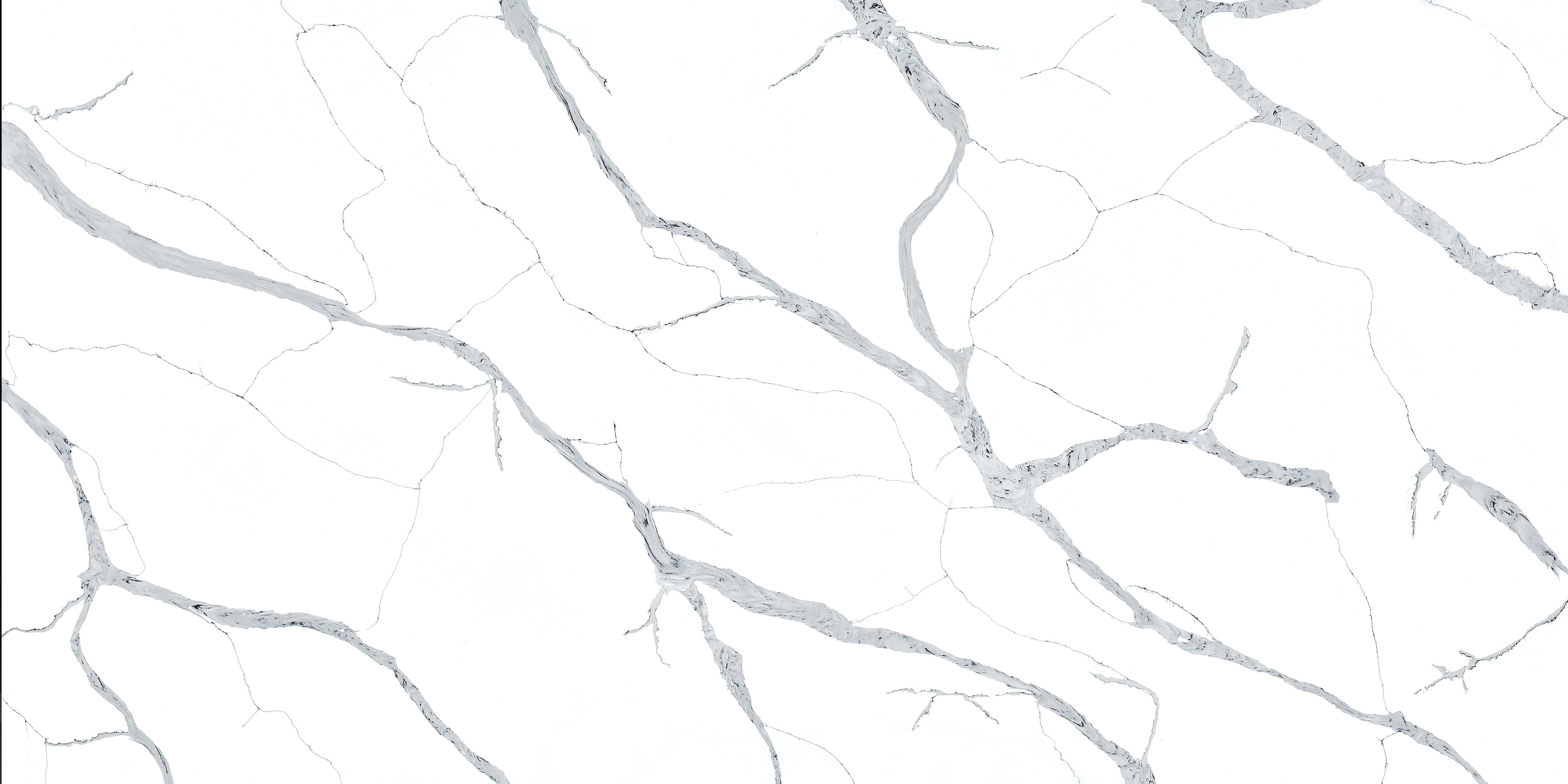

Taking inspiration from the wave marks of snow-capped mountains, the white base is embellished with natural gray patterns, resembling the freehand layering of wind-eroded ice rocks.

The soft light texture replicates the texture of the original stone, with undulating textures resembling an eternal dialogue between ridges and waves. The high hardness and anti-pollution structure are suitable for kitchen and bathroom countertops and background walls, capturing the flowing poetry of natural power in minimalism.

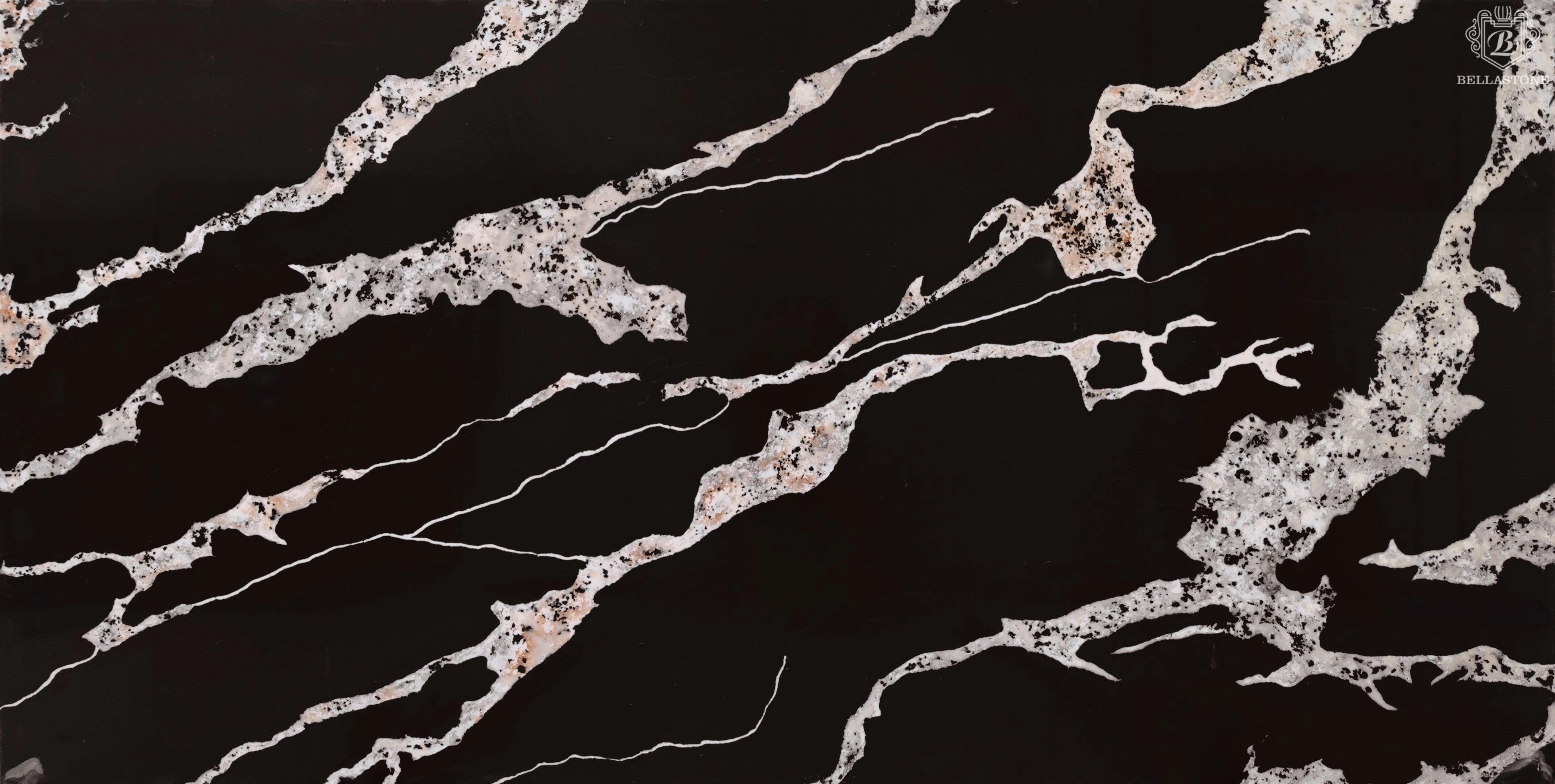

Bellastone Artificial Quartz Stone New Collection - BL9562 Black Silk

Inspired by the Dark Night Nebula, the ink black matrix flows with pink and white streaks, like fragments of star orbits scattered across the velvet universe.

Micro sparkling grains dotted among them resemble the birth of a new star, and the soft light surface replicates the touch of the Milky Way. The high hardness anti pollution structure is suitable for artistic countertops and fireplace background walls, playing a dynamic celestial poem in depth."

Bellastone Artificial Quartz Stone New Collection - BL9542-2 Golden Lyra

Taking inspiration from the orbit of the Lyra constellation, the soft beige base flows with liquid gold patterns, resembling a galaxy leaping on a stone. Stereoscopic silk veins replicate constellation trajectories, with a soft light layer blending the warmth of dusk.

The high hardness and anti pollution structure is suitable for luxury countertops and artistic backgrounds, allowing the space to play an eternal celestial melody.

Bellastone Artificial Quartz Stone New Collection - BL9537 Stream

Inspired by mountain streams, a pure white base is woven with agile light gray veins, like a natural poem of clear spring water flowing across an icefield.

The delicate texture replicates the dynamic movement of water, while the glossy surface radiates a moist, luminous quality. Its stain-resistant and wear-resistant structure is suited for minimalist countertops and feature walls, infusing the space with a tranquil yet fluid modern rhythm

Bellastone Artificial Quartz Stone New Collection - BL9543 Riga

Inspired by the pearl of the Baltic Sea, a pure white base is engraved with agile light golden veins, resembling the radiant glow of dawn over the ancient city of Riga. The delicate texture replicates the veins of natural marble, while the glossy surface exudes a luxurious. Its stain-resistant and wear-resistant structure is suited for luxury countertops and artistic feature walls, infusing the space with an elegant and timeless urban poetry

.

Bellastone Artificial Quartz Stone New Collection - BL9560 Calacatta Golden Renaissance

Inspired by the gold of the Renaissance, a pure white base flows with gilded veins, resembling sunlit traces forged within the Calacatta mineral veins. The delicate texture replicates the luxurious feel of natural stone patterns, while the glossy surface radiates a brilliant luster. Its stain-resistant and wear-resistant structure is suited for luxury countertops and artistic feature walls, infusing the space with a grand and dynamic epic poetry.

Bellastone Artificial Quartz Stone New Collection - BL9561 Calacatta Golden Silver

Inspired by the interplay of gilded gold and silver veins, a pure white base flows with dynamic golden patterns, resembling molten gold and silver threads woven into the natural canvas of Calacatta stone layers. The delicate texture replicates the luxurious feel of rare stone veins, while the glossy surface radiates a subtle brilliance. Its stain-resistant and wear-resistant structure makes it ideal for luxury countertops and artistic feature walls, infusing spaces with an elegant and timeless Renaissance poetry

Bellastone Artificial Quartz Stone New Collection - BL9566 Calacatta Drifting Snow

Inspired by snow falling upon Calacatta, a pure white base is elegantly veined with subtle grey streaks, resembling natural ink wash patterns of fresh snow gently covering rock layers. The delicate texture replicates the veins of rare stone, while the soft glossy surface exudes a serene quality. Its stain-resistant and wear-resistant structure makes it ideal for minimalist countertops and artistic feature walls, infusing spaces with a pure and timeless snowy landscape poetry.

Whether you're exploring design trends or planning your next build, our team is here to support with product advice, pricing, and tailored solutions.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

By clicking "Send Inquiry Now", I agree to your processing my personal data.

To see how to withdraw your consent, how to control your personal data, and how we process it, please see our Privacy Policy and Terms of Use.

© 2025 BELLASTONE. All Rights Reserved. | Privacy Policy | Terms and Conditions | Sitemap

Facebook

Linkedin

YouTube